MANUSsimOptimize - CNC Cycle Time Optimization

Automatically reduce CNC cycle times by detecting wasted moves, speeding up air cuts, and optimising feeds — all from your NC program.

Optimize Your NC Programs & Speed Up Your CNC Machinig Times by More than 20%

MANUSsimOptimize provides a cost-effective solution to the issue of air cuts during operation changes in NC program optimization. It accelerates feed rates and eliminates air cuts, improving CNC machining efficiency.

MANUSsimOptimize - Benefits

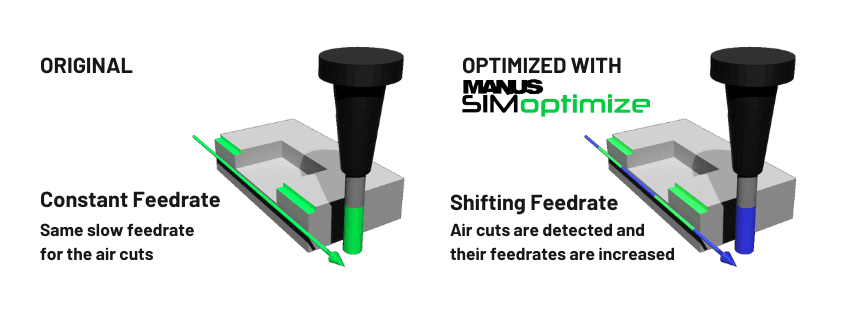

AIR CUT FEEDRATE OPTIMIZATION

All air cuts are detected & optimized automatically!

Air cuts (uncut tool paths) are headaches of all CNC programmers. You lose lots of time and money with these kind of senseless moves.

MANUSsimOptimize detects & optimizes feedrates of all uncut regions on your NC programs

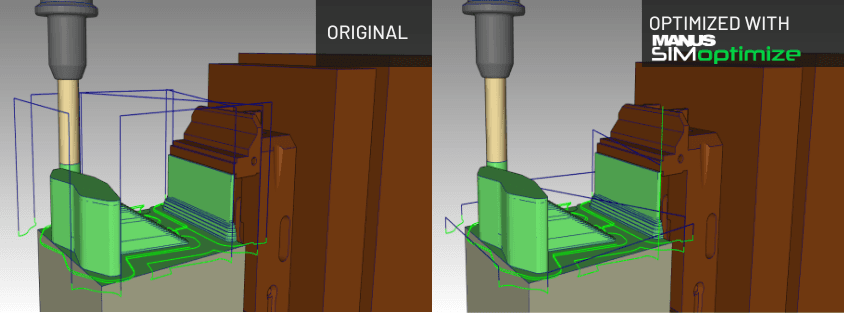

AIR CUT MINIMIZATION

Do not waste your time & money with unwanted & senseless home returns!

Almost all NC programs for multi-axis CNCs have unnecessary and senseless home returns.

These home returns and long cutting tool retracts

are detected and minimized automatically by MANUSsimOptimize.

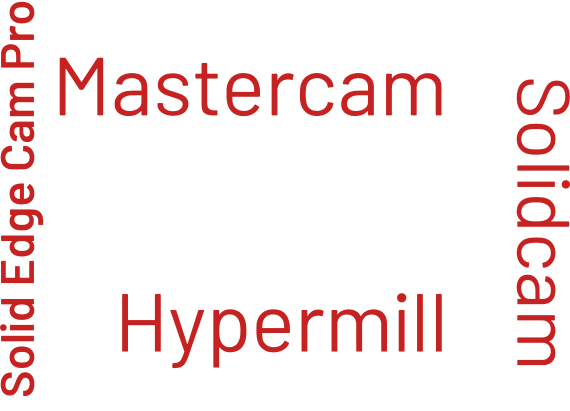

IT DOESN'T MATTER WHICH CAM YOU USE

We simulate & optimize your real NC programs

This means you can use it with any CAM program you want.

Moreover, this also means that you can use this tool on multiple CAM systems if you are a multi-CAM software user.

SIMULATE & OPTIMIZE AT THE SAME TIME

We use your real CNC digital twin while optimizing your NC program!

Unlike many other NC optimization tools on the market, we use the real CNC digital twin of your CNC machine, and we simulate the real NC program.

This means, we simulate & verify at the same time!

MANUSsimOptimize - Feature Videos

MANUSsim Optimize Air Cut Minimization

MANUSsim Optimize Air Cut Minimization 2

MANUSsim Optimize Physical Simulation + Cutting Optimization

Optimized Toolpath 1

Optimized Toolpath 2

Optimized Toolpath 3

What is MANUSsim Optimize?

Why machine shop trusts MANUS Software

Book a Demo

Contact us to discuss how this solution can benefit your operations.